Building a Case for CPQ Operating on PLM

/No Other Platform Provides the Needed Single-Source-of-Truth like PLM

CPQ draws on a wide variety of data and is critically process dependent. If ever there were applications that could use “single source of truth,” it is CPQ.

But, for many companies, spreadsheets, file folders, email exchanges and various home grown and internally maintained applications are their “CPQ-lite.” On top of all of this, the “change train” keeps barreling along. Data is never static. Change does not stop. Time-outs don’t exist. And, undoubtedly, the “intervention cycles” will be high and unsustainable.

Let’s recall the presentation from an earlier issue as a step toward making the case.

PLM Maturity Quadrant

Earlier this year we formulated the PLM Maturity Quadrant as illustrated in the diagram below.

The quadrant is comprised of two simple parameters. The x-axis shows the Data Cohesion variable and the y-axis characterizes Process Repeatability. The top right-hand quadrant represents the ideal PLM environment.

The Data Cohesion variable considers how well data is connected. The expression “single source of truth” is often associated with the goals of PLM. This suggests that users seeking to access part and/or product related data can go to ONE place. The data doesn’t have to be in a single repository, but linkages need to be in place.

The Process Repeatability vertical axis measures the repeatability of an organization’s processes. On one end of the spectrum, the processes are based on manual and verbal communications that are steeped in cultural and/or community knowledge and experiences.

Custom components inherently involve the review and input of other disciplines such as engineering, planning, manufacturing and purchasing for example. These activities are part of a process that also captures additional data such as specs, manufacturing processes, etc.

PLM for CPQ

As we stated, “CPQ draws on a wide variety of data and is very process dependent. If ever there were applications that could use “single source of truth”, it is CPQ.”

Herein is the opportunity. Do you buy a standalone CPQ application and glue the needed silos together? Or, do you consider building a foundation? One that serves the needs of CPQ, and establishes a beachhead for other multiple data/process applications such as new product introduction, configuration management, manufacturing process planning, and so on?

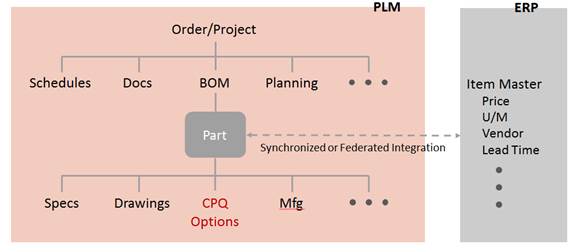

PLM platforms are the infrastructure of choice to deal with the varying data types and processes. The image below represents this data model idea.

Notice that we’ve represented it as a part-centric model. Parts are connected to other things and have various types of data associated with it. The “CPQ Options” (in red) exist as a CPQ characterization of the part. This data does not “live” outside of the part and order data. It is connected and is part of the overall process. This is a significant contrast to improvised models where data is spread about is difficult and potentially impossible to maintain the integrity of relationships throughout the quoting, manufacturing and delivery processes.

Our urging is to embrace what PLM has already accomplished. Leverage the foundation of PLM and accelerate access to CPQ capabilities. The investment will quickly be overshadowed by the returns.