The Practical PLM Newsletter - Issue 7, June 2016

/Practical PLM Newsletter

Pursuing the Promise of Product Lifecycle Management

Issue 7, July 2016

IN THIS ISSUE

- Introduction - PLM and Configure, Price and Quote (CPQ) Capabilities

- Business - What is CPQ?

- Value Premise - Accelerating the Sales Cycles

- Best Practices - Making the Case for CPQ Running on PLM

- Learning - Upcoming Webinar on CPQ and PLM in Practice

Introduction

PLM and Configure, Price and Quote (CPQ) Capabilities

Part 1 in a 2 Part Series:Extending the Value of PLM from Sales through Delivery

Have you heard any of these expressions within your shop? “I wish we could ship what we sold ... our quoting process is beginning to make us uncompetitive ... the cost of scrap and rework is unacceptable ... or, there is no way we can scale our business with the current quoting process.” If so, then this two part series may be of interest to you.

These comments reflect the current inefficiencies and lack of accuracy that can exist in the initial stages of the sales process. Unfortunately, the negative impact shows up in downstream product lifecycle activities such as product design, planning, manufacturing, delivery and support.

The solutions to these frustrating circumstances have been called, “product or BOM configurators,” “quote to cash,” “guided selling” and “mass customization.” But, the recent and trendy expression is, “configure, price and quote” or CPQ. In fact, recent and large acquisitions by Oracle and Salesforce have given CPQ significant visibility and awareness.

We believe this topic is vital to the engineering and manufacturing community. Moreover, we believe it has relevance to PLM. As we were developing the material for this newsletter, it quickly became apparent that the topics we wanted to cover exceeded the scope of our monthly newsletter. Hence, we decided to do a two part series.

In this first part, we kick things off by describing what CPQ is, followed by a discussion addressing one of the primary value propositions of CPQ – accelerating the sales cycle. In the Best Practices section, we put forth an argument for PLM as the foundation for CPQ.

Lastly, we are announcing a webinar to illustrate CPQ functionality operating in a PLM environment.

In part two, we will be drilling into the workings of CPQ and talking about implementation considerations. One of the topics will be design automation functionality that allows users to modify various parameters, which in turn automatically generates the needed geometry in 3D CAD drawings.

For continuity and ease of learning, we suggest you digest the following material in the sequence presented.

BUSINESS

What is CPQ and Why Should it Matter?

It’s more than just a point solution … it’s a strategy

CPQ helps companies configure product offerings, price them and produce quotes and proposals. It is functionality used by sales people and can be extended to customers via a self-serve portal. Ultimately, it is about minimizing the quoting effort and accurately conveying the specific requirements for downstream processes. As can be seen in the acronym itself, CPQ involves multiple disciplines. The elements of a quote include …

- product and part data, what’s off-the-shelf and what needs to be designed, valid relationships, part options and constraints, and availability

- pricing data that may need to take into account geographies, local regulations, economic benefits, manufacturing costs, competition, margins and discounting

- quoting conditions such as scheduling, credit status, and payment options

Applying CPQ is not for the single SKU (stock keeping unit) company, rather for companies that offer product lines with multiple configuration/custom options for each unique customer order.

Let’s highlight the benefits that are offered by CPQ capabilities. Check out the illustration below.

Forbes article, “Five Ways Cloud-Based CPQ Increases Sales Effectiveness and Drives up CRM Adoption”, Apr 17, 2016, by Louis Columbus

Lead-to-sale increases by 30%! Are you kidding? That’s a compelling, eye-opening number. That benefit alone should be a compelling driver for CPQ.

BENEFITS

Accelerating the Sales Cycles

Would accelerating your sales process drive additional revenue?

Are you leaving money on the table? We think so. Do you? Consultants like Louis Columbus do as referenced in the diagram above. He points to the real possibility of a lead-to-sale increase of 30%. In similar studies, improvements of 5% to 10% in revenues are realized by simply producing quotes faster along with refining costs that no longer have to be estimated.

So where does this uptick come from? Let’s do a little math to see how these claims can be made.

Say your organization does a 1,000 quotes a year, driving 100% of the company’s revenue. Each quote takes approximately five days. The win rate is 15% within a year. And, let’s assume 250 working days a year.

Without augmenting staffing requirements, let’s estimate a productivity improvement of just 10% (per the table above) of proposal development time by leveraging CPQ capabilities. This 10% savings allows for the production of an additional 110 proposals per year. Using the average close rate of 15%, this means an additional 17 proposals awarded, producing a 12% increase in revenues.

Of course, there are numerous assumptions buried in this calculation. This includes variations in quoting cycles, staffing to generate quotes, deal flow, manufacturing capacity, delivery capacity, and so on. And … this is not a linear function. But, the important takeaway is that CPQ can deliver additional revenues with the same resources. Can your company ignore or overlook this revenue impact?

BEST PRACTICES

Building a Case for CPQ Operating on PLM

No Other Platform Provides the Needed Single-Source-of-Truth like PLM

CPQ draws on a wide variety of data and is critically process dependent. If ever there were applications that could use “single source of truth,” it is CPQ.

But, for many companies, spreadsheets, file folders, email exchanges and various home grown and internally maintained applications are their “CPQ-lite.” On top of all of this, the “change train” keeps barreling along. Data is never static. Change does not stop. Time-outs don’t exist. And, undoubtedly, the “intervention cycles” will be high and unsustainable.

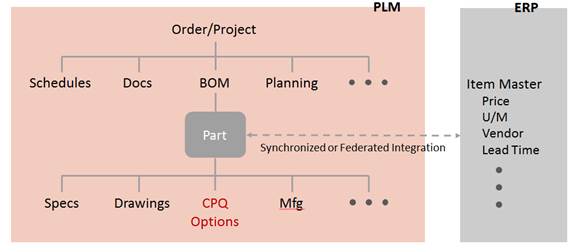

Let’s recall the presentation from an earlier issue as a step toward making the case.

PLM Maturity Quadrant

Earlier this year we formulated the PLM Maturity Quadrant as illustrated in the diagram below.

The quadrant is comprised of two simple parameters. The x-axis shows the Data Cohesion variable and the y-axis characterizes Process Repeatability. The top right-hand quadrant represents the ideal PLM environment.

The Data Cohesion variable considers how well data is connected. The expression “single source of truth” is often associated with the goals of PLM. This suggests that users seeking to access part and/or product related data can go to ONE place. The data doesn’t have to be in a single repository, but linkages need to be in place.

The Process Repeatability vertical axis measures the repeatability of an organization’s processes. On one end of the spectrum, the processes are based on manual and verbal communications that are steeped in cultural and/or community knowledge and experiences.

Custom components inherently involve the review and input of other disciplines such as engineering, planning, manufacturing and purchasing for example. These activities are part of a process that also captures additional data such as specs, manufacturing processes, etc.

PLM for CPQ

As we stated, “CPQ draws on a wide variety of data and is very process dependent. If ever there were applications that could use “single source of truth”, it is CPQ.”

Herein is the opportunity. Do you buy a standalone CPQ application and glue the needed silos together? Or, do you consider building a foundation? One that serves the needs of CPQ, and establishes a beachhead for other multiple data/process applications such as new product introduction, configuration management, manufacturing process planning, and so on?

PLM platforms are the infrastructure of choice to deal with the varying data types and processes. The image below represents this data model idea.

Notice that we’ve represented it as a part-centric model. Parts are connected to other things and have various types of data associated with it. The “CPQ Options” (in red) exist as a CPQ characterization of the part. This data does not “live” outside of the part and order data. It is connected and is part of the overall process. This is a significant contrast to improvised models where data is spread about is difficult and potentially impossible to maintain the integrity of relationships throughout the quoting, manufacturing and delivery processes.

Our urging is to embrace what PLM has already accomplished. Leverage the foundation of PLM and accelerate access to CPQ capabilities. The investment will quickly be overshadowed by the returns.

LEARNING

Upcoming Webinar: CPQ Integrated with Aras PLM

Save the date for August 26, 2016

We’ve made the argument for running CPQ on PLM. But what does it actually look like?

This webinar will illustrate a BOM configuration process. We will go through the complete sequence involved in developing and producing a valid quote, including the initial capture process and the workflow to solicit input from engineering, planning, manufacturing, and purchasing.

Also, we’ll show you what went into making this process possible. We’ll describe the part and bill data structures, CPQ parameters and relationship variables.

Contact

This Practical PLM newsletter is authored and edited by The vdR Group, Inc. (vdR) along with contributions from selected partners. It is scheduled to be published the second Tuesday of every month. Delivery dates may vary.

Your editors are Martin van der Roest and Dick Bourke. We welcome your comments/questions. You can direct them to martin@vdr.com or dickb@bourkeconsulting.com. If applicable, we will respond in a following newsletter.

Mission

Our mission is to help engineering/manufacturing companies achieve the promise of product lifecycle management (PLM). We do this by exploring practical action steps that drive business value and that yield measurable revenue contributions and reduced expenses.

PLM is a combination of business strategies, best practices and technology. Hence, this monthly newsletter looks at the business drivers, best practices, applications and education.

Aras is the technology vehicle of choice for vdR. vdR is a full-service partner of Aras.

Copyright © 2016 The vdR Group, Inc., All rights reserved.

All trademarks belong to their respective holders. Content, responses and opinions expressed are not necessarily shared by Aras.

Our address

The vdR Group, Inc.

1592 North Batavia

Orange, CA92867

You can opt-out of this newsletter here.