The Practical PLM Newsletter - Issue 2, January 2016

/In This Issue

- Introduction - Happy New Year

- News - ACE 2016 – Aras Customer Event Coming up in March and Triangle Package Leverages PLM to Unify Enterprise Processes

- Business - Pursuing the Promise of PLM – Part 1

- Application - Self-Serve Reporting – Interview with Lopa Subramanian

- Under the Hood - Developing Workflow Components in Aras

- In The Labs - Proposal Management for Engineer/Build-to-Order

- Learning - Webinars, Conferences, Training, and More

INTRODUCTION

Happy New Year

Kicking off the year with practical insights

We are pleased to kick-off the year with a multipart series geared to the business drivers of PLM. We’re calling this series “Pursuing the Promise of PLM.” In this first part, we’re laying the groundwork for why PLM needs to be a strategic initiative with executive sponsorship all the way from the top.

On the other end of the spectrum, we get under the hood on workflow ideas.

We’re also introducing our “In the Labs” section to the newsletter. This section is dedicated to projects and solutions underway that aim to solve some of the challenges that our customers are facing. In this issue, we’ll talk about Proposal Management for Engineer/Build-to-Order organizations.

There is a lot of reading here. Take your time. Try an article and get to another article at a later date. By the time you’re done, next month’s issue will be coming out.

NEWS

ACE 2016 – A Must Attend Event

Aras Customer Event, Detroit, MI - March 15 - 17, 2016

Join the Aras community on March 15 - 17 for ACE 2016 at the Detroit Marriott Renaissance Center. ACE 2016 is a great place to learn the latest PLM best practices, network with Aras users and partners, see the latest solutions and find out what Aras has in store for the future. Moreover, existing Aras customers will showcase how they’ve leveraged the technology and share industry-specific tips. Anyone can register and attend at no cost, meals included. For more information, check it out here. Remember to visit our booth.

Murata Manufacturing Using PLM to Unify Enterprise Processes

Based on Press Release from December 15, 2015

Murata Manufacturing Corporation is a global organization that designs, manufactures and sells ceramic-based passive electronic components and solutions. They recently announced that they are replacing their legacy PLM system with Aras’ enterprise PLM platform.

What stands out in this press release is what we keep seeing over and over. It’s about improving collaboration and processes. Moreover, it has the flexibility and customizability to support the realities of business … change. This includes everything from accommodating end-user preferences to responding to enterprise-wide business initiatives.

Therein is the balance that needs to be struck. Competition is changing daily and globally. Businesses need to remain fleet-footed and efficient. Hence, solutions must be flexible enough without falling into a costly “science project” to make needed adjustments.

For more information, the press release can be read here.

BUSINESS

Pursuing the Promise of PLM – Part 1

PLM is a business initiative … not a tactical project

By Martin van der Roest

Personally, one of my go-to content sources is TED talks. In particular, I have enjoyed Simon Sinek. He’s an author best known for popularizing the concept of "the golden circle" and to "Start with Why.” In one of his talks, Sinek encourages us to understand “why” we pursue an idea, and then dig into the “how” and “what” later. By doing so, the result is a vision and energy that transcends the morass of tactical details. A prime example … Steve Jobs is the iconic “why guy.”

I recently participated in a meeting with a company that underscores the importance of being powered by “why.” The COO hosted it. He had his sales, planning, engineering, and delivery/services staff participate to better understand the potential value of PLM.

Throughout our discussions, the team used such phrases as “we need to be more competitive,” “we’re too inefficient,” “scrap and rework are too high,” and so on. This was not a meeting concerned with how to automate the transfer of the released bill to ERP or any other transactional tactic. No, this was a meeting where the team was pursuing the “why.” Bravo to the COO.

Just as the different departments were represented at this meeting, PLM inherently crosses departmental boundaries. The data and processes are not isolated to a handful of folks in engineering or quality control. Without a company-wide “why” approach, we reinforce islands of automation, processes and behaviors.

For example, how many CAD vaults are stood up for the benefit of CAD users, without regard to others in the organization? The engineering manager needs to solve immediate issues. Every well-intended department leader tackles their own issues. This situation is completely understandable, but not in support of a broader initiative, i.e., PLM. My goodness, it’s hard enough to change out an ERP solution.

Certainly, ERP has its place. But, I contend that PLM is where a company is going to drive innovation, competitiveness, increased revenues and reduced cost of goods. There is no other solution in a company that does this! ERP is a vital transactional platform. A PLM strategy driven by visionary “whys” is the magic wand in the right leader’s hand.

So, if you are management, and there is no PLM strategy, 2016 may be an advantageous time to start.

This series will look at the “whys” and the resulting value they create. We’ll drill into the various challenges that come with the ugly reality of disparate databases and applications, isolated processes and outline strategies and action steps to help companies pursue the promise of PLM.

APPLICATIONS

Self-Serve Reporting Module

An Interview with Lopa Subramanian, Aras Product Manager

Martin: Before we start, give us a quick background of your experience and what you are responsible for today.

Lopa: I’m a mechanical engineer by education, and I have been in PLM and the enterprise software space for my whole career. I started in services with SDRC Metaphase and then moved to Aspect Development/i2 in their supplier relationship management area. I gained great experience in both services and presales working with utility companies, high-tech, apparel, retail, industrial and the auto industry. Prior to joining Aras, I spent a number of years at Siemens PLM working with Teamcenter.

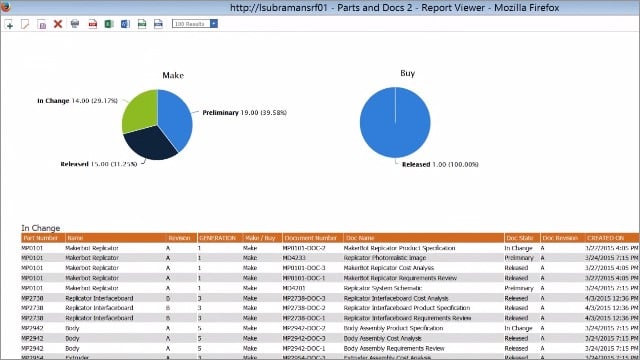

Martin: Give us a summary of the Self-Service Reporting solution.

Lopa: Self-Service Reporting is specifically designed with end users in mind. An admin is not needed to set up reports although an admin can use this module as well. The users go into Aras Innovator, click on the item types and the properties they want to report on and go through a wizard-like interface to produce a report. They can then save that report (definition) and share it with their colleagues - people in different groups or identities. The saved reports can be run as needed. Users have options to format, include aggregations like counts or averages and incorporate charts and graphs as well as pivots in reports. It gives users a lot of flexibility without the need to have programming skills.

Martin: That raises several questions. First, did Aras leverage a reporting technology to support this or is this an original work that you guys did?

Lopa: We licensed a third party solution and wrapped it with Aras specific capabilities. Typically, when you think of reporting software, it is very database orientated. Users see table names and column names that may not mean much to the end user. We wanted to change that, so we’ve taken the engine and put our UI on it. A user will see familiar Item names and tab names instead of raw database names.

Of course, we store all the definitions in the database. So, if you are a consultant - that’s you VARs - you can define a bunch of reports in your data base and package that up for deployment on a customer’s database.

Martin: Nice. You mentioned graphics. Explain that further.

Lopa: Yes, as part of the wizard, users will find a tab for charts. They can add and configure as many charts as they want using the UI. You can add a pie chart or bar chart on the fly to the report, and then store the report definition.

Martin: In terms of the different presentation options, it sounds like you have the text and graphics. Is there an option to include images? Say, for example, I have images of parts, and I want to list them almost like a catalog.

Lopa: Yes, you have access to images and colors, and all of those should work seamlessly.

Martin: That type of output reporting formatting options are available?

Lopa: The report can be exported to PDF, EXCEL, WORD, CSV and XML.

Martin: That’s great. Talk about security and what users can see and not see.

Lopa: Permissions in Innovator are honored, and that’s a big deal! You don’t want people to be reporting on things they don’t have access to. By design, reporting only shows users the items they have access to.

Martin: Are there any setup, prerequisites or advance considerations for operating this application?

Lopa: First, it is a subscriber-only solution. You do need a separate activation key and it is included in the subscription at no extra charge. There is no extra setup … you simply install Innovator and the reporting module is included.

At the moment, there are no canned reports that are deployed with it. Maybe at some point we will think of building canned reports out of the box, but since the UI is easy to use, and pretty straight forward, users can quickly build reports themselves.

Martin: Nice. How long has this been out?

Lopa: It has been out since SP3, since the end of July.

Martin: Is there a demo online available?

Lopa: Yes, there is a short demo and a long demo on aras.com. (NOTE: We have referenced this demo in the Sales Assets repository).

UNDER THE HOOD

Developing Workflow Components in Aras

By Ben Desmarais, vdR Group Senior Implementation Manager

I’ve been doing PLM solutions for nearly two decades now. Crafting workflow solutions are essential for most any implementation effort. I was recently involved in designing and configuring workflow processes for a project, and a couple of things occurred that prompted me to want to share some thoughts.

First, lifecycle stages go hand-in-hand with workflows. Think of workflows as moving a collection of items through a process. As an item moves through the process, it is likely to change states. For example, if an item is being changed, then once a change process is activated for that item, the lifecycle state might be assigned to “work-in-process” or WIP.

On top of that, there may be certain user roles and rights associated with an item and its various states.

For expediency sake, I like using a simple and fast modeling tool like Visio to lay out all the steps. You can use business process modeling techniques that incorporate “swim lanes” to help visualize the process as well. The important thing I have found is to refine the process with end users using something fast and simple.

Recommended Steps

My recommended steps for developing workflows are…

- identify all the items to be treated

- identify their possible lifecycle stages and access criteria

- use a simple and fast modeling tool to capture requirements and review with the customer

- start building the items and workflow in Aras Innovator

Nailing the process before configuring in Aras is key. Get feedback from all the participants early and upfront.

Normally, there is a lead person or a team that will do the initial requirements for workflow process. Sometimes it’s already documented in a procedure document. After you get an understanding of the process and model it, go back to each participant in the workflow and confirm the workflow will work for their needs. Some participants will not care about a specific activity or activities in the workflow process. That’s fine. Focus on the activities they will interact with. Make sure to document any task they will do when assigned to them. Ask them about any specific requirements they may have before or after their workflow activity is assigned to them or promoted to the next activity.

We use a form that goes out to the users that will be involved. We want to know the tasks, lifecycle, assignments, notifications and alerts, to name a few.

I’ll talk about methods in another post. But, the important thing here is a method can be connected to workflow processes. It is customer specific code that can be executed at different stages in the workflow process. For example, once a workflow is complete, a method can be used to update an external system (e.g., ERP) upon release.

IN THE LABS

Proposal Management Module

A “Quote-to-Cash” Extension for Engineer/Build-to-Order Organizations

You may have heard about this expression “Quote to Cash.” Admittedly, it can sound a bit flippant. If only it were that easy. But, what if you could create significant efficiencies in the proposal process and drive cash in a shorter period of time?

Well, that’s the idea behind one of our newest lab projects… the Proposal Management Module. The goal is to help sales capture requirements, repurpose those into a proposal, pass the information on directly to planning and engineering, and do this without loss of “data fidelity”. If this process can be accelerated, then it stands to reason that the potential for delivery and invoicing are shortened as well.

Organizations involved in offering engineer/build-to-order solutions must capture requirements at the earliest stages of an opportunity. Capturing is done, of course, but based on what we are seeing, it often happens with spreadsheets, Word documents and email. After a sale, this data works its way downstream. This unorganized data loses significant fidelity as it cascades from planning to manufacturing and ultimately to installation. In situations like this, the delivery and customer support teams bear a heavy burden. And, of course, there is a financial cost. Cost of goods as represented by scrap, rework, labor and staff morale and brand image.

Putting PLM into the Sales Process

So why not start the product lifecycle activities during the sales process?

This is not a sales force automation activity. This is a requirements capture and proposal automation process. It augments and accelerates what sales individuals do on a daily basis.

The key task is to capture requirements at its earliest stages of the proposal process. The data captured during this sales process are repurposed into two principal deliverables.

- a comprehensive proposal that reflects all the requirements and the desired outcomes communicated by the prospect

- a complete delineation of the requirements and tasks for planning, engineering and manufacturing

To break it down a bit, let’s start with requirements capture. As the sales or account managers are engaging with an opportunity, scripted requirements are gathered to ensure all needed aspects for an engineer/build-to-order solution are satisfied. The capturing process can occur over multiple conversations/meetings with the prospect. Rather than try to reflect these in word documents or spreadsheets and emails, the proposal automation components would reuse all the captured data and automate the production of a proposal.

Of course, other disciplines can participate in this process as well, including planning to identify scheduling, engineering to design custom components and purchasing to support long lead item planning.

Once the proposal is accepted, the proposed project is activated, and all the requirements are now immediately available for downstream disciplines.

Aside from the benefits previously mentioned, the organization has also established repeatability for the proposal process.

Driving repeatability is a cornerstone of product lifecycle management. Moreover, it allows everyone to work to the same processes, removing the potential challenges of tribal knowledge, cultural conditioning, and other discretionary decisions that go with just being human.

Building on what we have

The exciting aspect of this is that we will be leveraging Aras application modules, including Requirements Management, Project Management, BOM, and most importantly, Technical Publications.

Let’s pause on Technical Publications. In conversations about the Technical Publications module, we’ve often found many users are confused. The traditional term Technical Publications or TechPubs seems to have conjured up the idea of a discipline that is concerned with researching, writing, and illustrating technical documentation for products.

As an example, Adobe’s Framemaker has had a historical role as a proven solution. In our context, however, TechPubs is all about the automated creation of content based on the reuse of technical data. This content can be marketing brochures, website content, CPG packaging, or even a sales proposal.

If you have ideas about what a proposal management module may offer, please let us know. We would love to get your input to incorporate while this effort is in the pre-release stage.

LEARNING

Upcoming Webinar

The Business Case for PLM: Finding Immediate Value

Save the Date: January 15, 2016 at 11:30 AM PST – Register Here

When most people think about PLM, the last thing that comes to mind is “immediate value.” A recent survey found that 25% of managers responsible for product development are hesitant to invest in PLM due to previous poor experiences. Yet, 70% of companies with dedicated PLM solutions have scraped major portions due to either low acceptance or budget overruns.

Join Martin van der Roest and Hiep Tran and learn how to overcome these challenges by focusing on small incremental “wins” that drive the process transformations needed to fully realize the power of PLM. As companies face increasingly globalized value chains and competitive pressures, there is an urgency to find real and immediate value within PLM.

Save the Date: January 15, 2016, at 11:30 AM PST

Contact

This Practical PLM newsletter is authored and edited by The vdR Group, Inc. (vdR) along with contributions from selected partners. It is scheduled to be published the second Tuesday of every month. Delivery dates may vary depending on holidays.

Your editors are Martin van der Roest and Dick Bourke. Your comments/questions are welcome; you can direct them to martin@vdr.com or dickb@bourkeconsulting.com. If applicable, we will respond in a future newsletter.

Mission

Our mission is to help engineering/manufacturing companies achieve the promise of product lifecycle management (PLM). We do this by exploring practical action steps that drive business value and yield measurable revenue contributions and reduced expenses.

PLM is a combination of business strategies, best practices and technology. Hence, this monthly newsletter looks at business drivers, applications, processes, along with considerations for various technologies.

The Aras PLM platform is a cornerstone of this trifecta. Aras is the fast growing PLM vendor today. The vdR Group is a full-service partner of Aras serving engineering and manufacturing companies in North America.

Copyright © 2016 The vdR Group, Inc., All rights reserved.

All trademarks belong to their respective holders. Content, responses and opinions expressed are not necessarily shared by Aras.

Our address is …

The vdR Group, Inc.

1592 North Batavia

Orange, CA92867