SYNCHRONIZE ENGINEERING AND MANUFACTURING PROCESSES TO IMPROVE OPERATIONS

As organizations strive to reduce time to market and minimize costly delays and rework, integration between PLM and ERP is a prerequisite, ensuring synchronization of the engineering and manufacturing views of the BOM and the change process.

Get Your Business in Sync

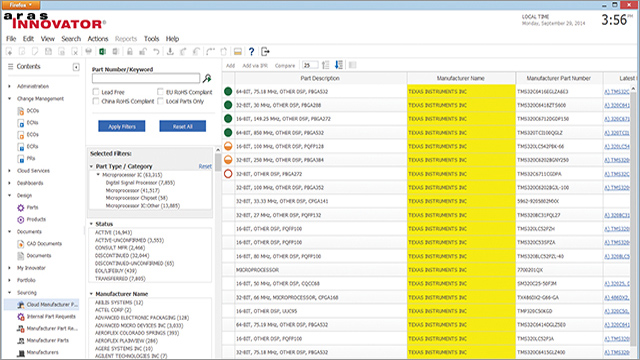

The Aras integration for ERP provides an effective integration of data, structures and workflow supporting part and BOM release and engineering change processes.

Key Features

- Bi-directional exchange of documents, CAD files, BOMs, parts, classification, item status and more

- Workflow integration linking release and change processes between PLM and ERP

- Integrate with multiple ERP systems

- User interface integration

Imperial Tobacco Group: Making the Aras PLM Choice

Watch how Imperial Tobacco Group came to the conclusion that Aras was the right PLM system for them. Imperial Tobacco Group plc (ITG) is a British multinational tobacco company headquartered in Bristol, United Kingdom. It is the world's fourth-largest cigarette company measured by market share and the world's largest producer of cigars, fine-cut tobacco and tobacco papers.

Benefits

- Reduces the workload associated with the release and change processes

- Reduces the likelihood of costly and time-consuming errors leading to excess inventory, scrap and rework

- Brings products to market faster

- Increases customer satisfaction

Find Out More

Aras Component Engineering Demo

See Configuration & Change Management process changes that impact the business at the enterprise level.

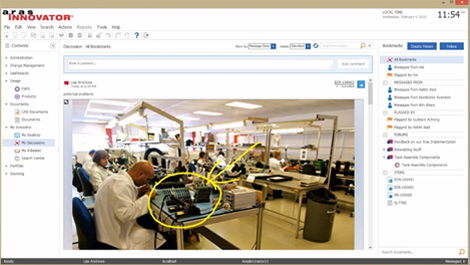

Aras Innovator 11: Visual Collaboration

Watch this on-demand webcast to get an introduction to visual collaboration and see Aras Innovator 11 in action.

Resilient Product Lifecycle Management White Paper

Discover how Aras PLM is a flexible, scalable and resilient product innovation platform that can handle today's complexity.